Innovation is a central pillar of Bachem’s success. Our dedicated teams explore and develop new technologies to bring innovative solutions to our partner’s needs.

Molecular Hiving™ Technology

BACHEM and Jitsubo have signed an exclusive licensing agreement for Jitsubo’s Molecular Hiving™ technology. The use of this technology allows for more environmentally friendly chemistry, reduced manufacturing costs and improved sustainability. Various projects for active pharmaceutical ingredients (API) as well as cosmetic peptides have already been initiated and successfully realized with Jitsubo’s technology at Bachem.

Molecular Hiving™ technology is especially suitable for the synthesis of peptidic ingredients for cosmetic products, as Carcinogenic, mutagenic, or toxic for reproduction (CMR) solvents and reagents can entirely be avoided during the manufacturing process. The technology is also suitable for oligonucleotide synthesis.

Bachem is an associate member of the American Chemical Society Green Chemistry Institute Pharmaceutical Roundtable to exchange information and ideas with other companies engaged in Green Chemistry, and to contribute to the goals of the American Chemical Society Green Chemistry Institute.

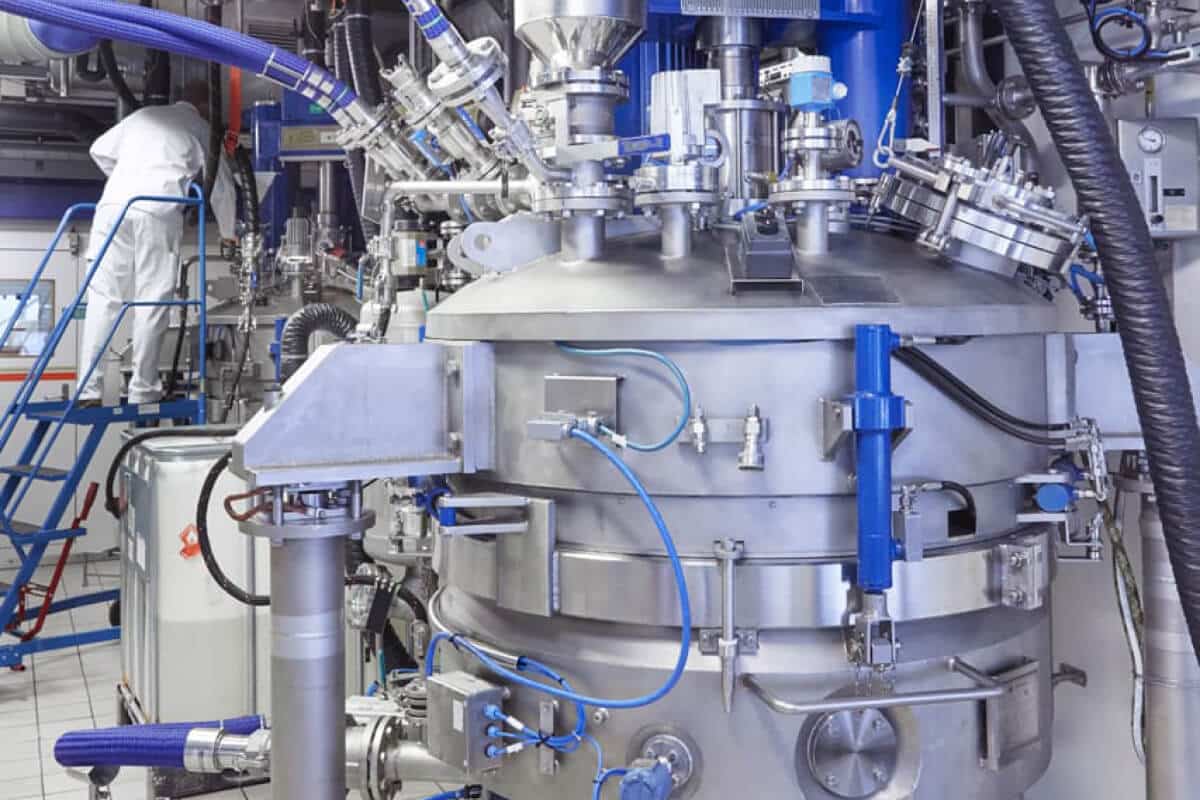

Peptide Purification

Currently, SPPS (solid phase peptide synthesis) is the go-to method for peptide synthesis. It is a rapid, orthogonal and efficient process. SPPS is able to synthesize sets of peptides in parallel, while the go-to purification method, RP-HPLC (LC), is a linear process and can represent the bottleneck of peptide development and manufacturing.

The new purification method introduced in this whitepaper extends the previous features of SPPS to the purification of peptides. The catch-and-release platform, termed Peptide Easy Clean (PEC), developed by Belyntic in collaboration with Bachem, enables the successful and innovative purification of peptides.

Redesign SPPS for Green Chemistry

We are committed to sustainability by taking responsibility towards our employees, the society, and the environment. In cooperation with Novo Nordisk we aim to redesign our processes to minimize the use and generation of hazardous substances, and reduce the environmental impact. In the pharmaceutical industry, solvent consumption generates a significant environmental footprint. Research is conducted to decrease solvent volumes or for substituting them by environmentally benign solvents. Both represents an impactful innovation in API production processes.

Innovation Matters

Click here >>

Webinars

Click here >>