Today’s technologies for producing oligonucleotides come with a high burden in terms of process mass intensity (PMI)1PMI is a measure of the quantity of raw material to produce one kilogram of isolated API.. As published in a recent paper, the PMI for producing one kilogram of oligonucleotides with 20 building blocks is around 4300 kilogram of waste per kilogram of active pharmaceutical ingredient (API)2DOI: 10.1039/d2gc04547h.

It is no wonder that scientists in oligonucleotide manufacturing organizations worldwide are heavily engaged in finding new manufacturing routes to produce these active pharmaceutical ingredients (API) in a more sustainable way with a lower PMI. In order to do so they are investigating both new ways of synthesizing and new ways of purifying these substances. Their main objective is to reduce the consumption of organic solvents in these processes, as this is a major factor contributing to a high PMI.

Hybrid synthesis for scalable oligonucleotide manufacturing

Very promising options regarding synthesis of these substances are hybrid approaches combining the best of the two traditional synthesizing techniques solution-phase oligonucleotide synthesis and solid-phase oligonucleotide synthesis (SPOS). Bachem’s new tag-assisted one-pot liquid-phase oligonucleotide synthesis (TOP LPOS) uses liquid anchor molecules, called tags or pseudo-solid phase protection groups, on which the growing oligonucleotide is assembled.

This means the advantage of SPOS, which is the separation of the product from byproducts and reagents, is preserved using the tag instead of a solid-phase resin. Limitations of SPOS such as a restricted loading capacity of the solid-phase resin is not a factor in TOP LPOS. That’s why a higher volume yield can be achieved.

Advantages of one-pot Liquid-phase oligo synthesis

The listed advantages are preserved in tag-assisted one-pot liquid-phase oligonucleotide synthesis

- linear reaction kinetics in homogeneous solution

- reagents and building blocks; that can be used mostly in stoichiometric amounts and not in excess and,

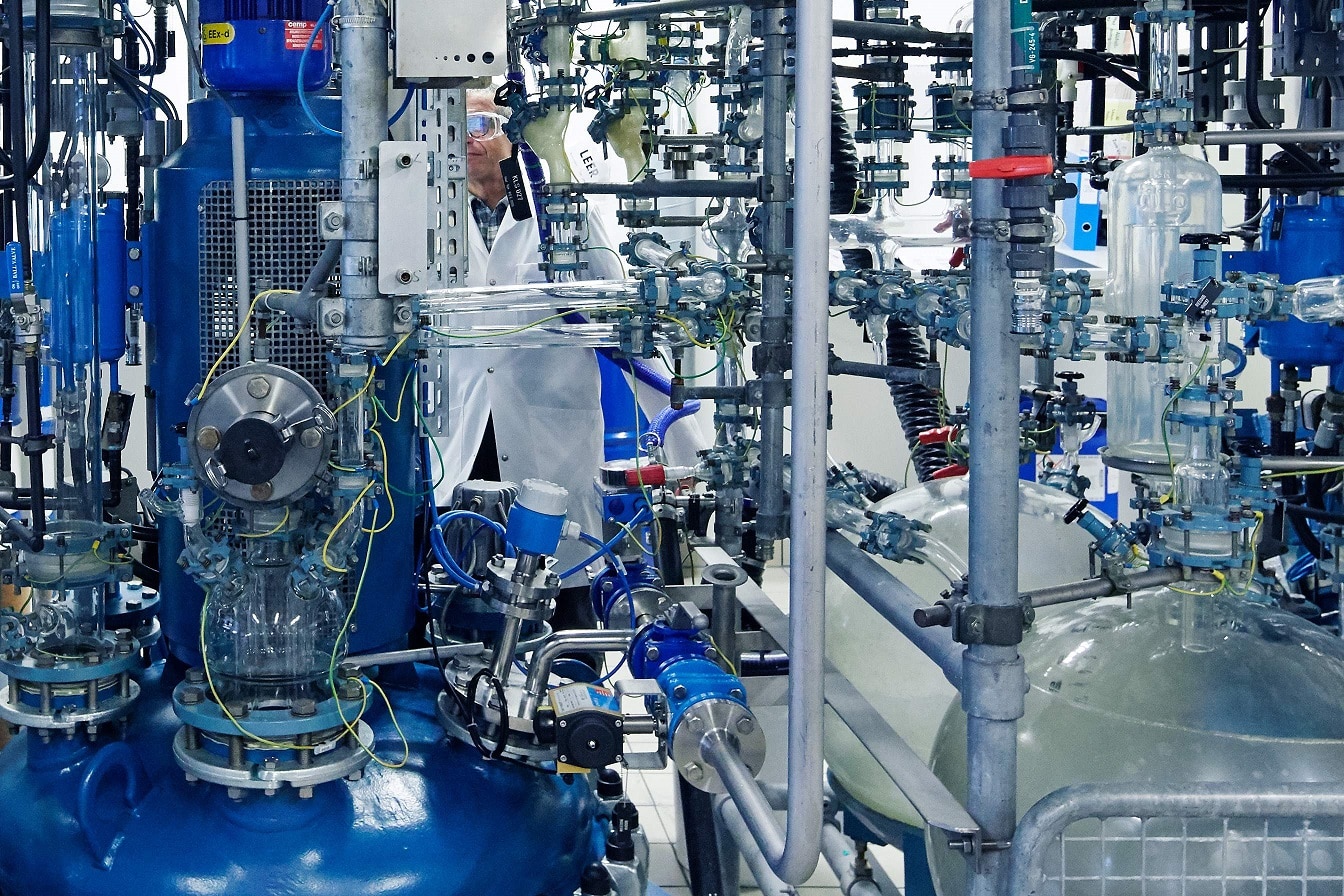

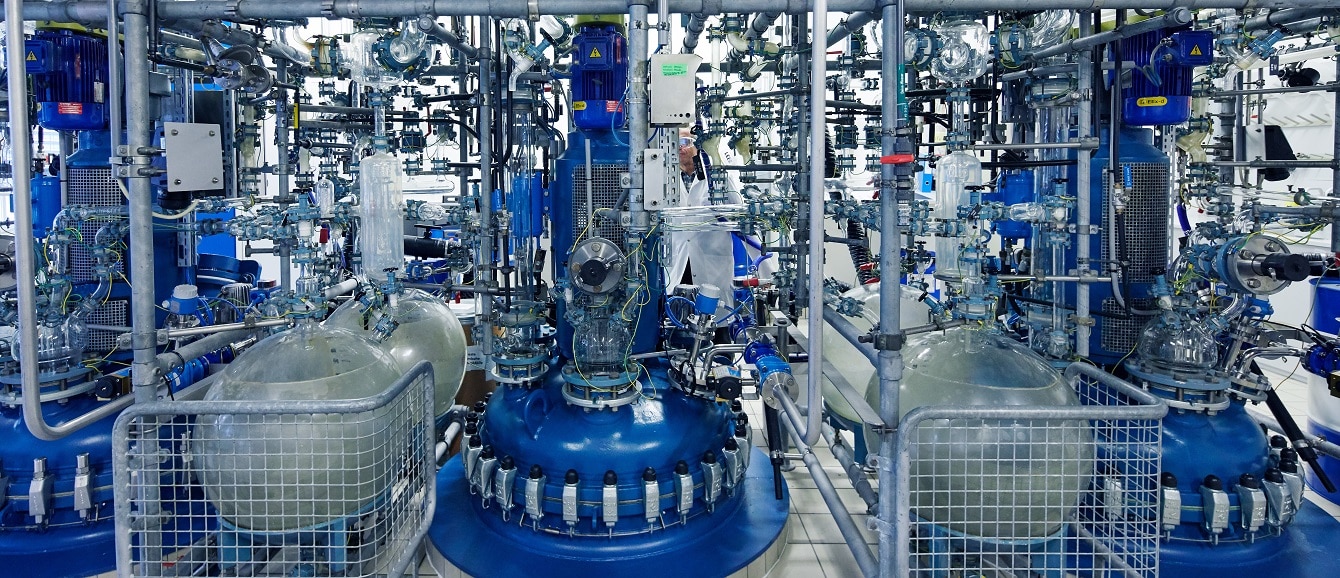

- relatively simple one-pot reactor design

How does tag-assisted one-pot liquid-phase synthesis work?

The same repetitive chemical steps as in classic fixed-bed flow through SPOS are used. However, excessive washing steps after each cycle are not necessary. Reaction debris is removed with aqueous extraction. Due to this, a considerable reduction in PMI compared to automated classic SPOS can be expected as half of PMI in synthesis in solid-phase technologies is contributed by the solvents used in washing steps.

Furthermore, we were able to develop a process using halogen-free solvents. The newly developed tags don’t interfere with the standard oligonucleotide synthesis and can be cleaved after synthesis under basic global deprotection conditions. This technology is ideal for the synthesis of oligonucleotide fragments which are then used for enzymatic ligation reactions. In addition, the non-heterogeneous process is also ideally suited for large-scale oligo manufacturing due to its one-pot design and limitless scalability.

Interested in more details about the tag- assisted one-pot liquid-phase oligo synthesis?

Watch our webinar:

Subscribe to our general newsletter

"*" indicates required fields

- 1PMI is a measure of the quantity of raw material to produce one kilogram of isolated API.

- 2DOI: 10.1039/d2gc04547h