The generic medicines industry ensures global access to affordable, high-quality medications for hundreds of millions of patients around the world. Swift to respond to evolving healthcare needs, they play a vital role in supplying essential medications and drugs for rare and thereby significantly contributing to improved global health and socioeconomic outcomes. Given various competitive and logistic challenges, generic medicine companies must constantly evaluate resilience and adaptability measures to changing market and global operation environments.

Especially for pharmaceutical manufacturing, API production expertise is a crucial component for efficiency and affordability. At Bachem, we utilize technological and methodological synergies in the synthesis of different API to contribute our part in making drugs affordable for a large number of patients.

This article explores how production expertise in the synthesis of Gonadotropin-releasing hormone (GnRH) analogues such Goserelin, Leuprorelin and Triptorelin not only enhances cost efficiency, but also brings about consistent quality, a secured supply chain, research advancements, and accelerated product development.

The complex world of peptide API synthesis

Peptide APIs (Active Pharmaceutical Ingredients) present a unique set of challenges in the production process. The synthetic manufacturing of these intricate molecules requires a nuanced understanding of both the chemical and biological aspects involved.

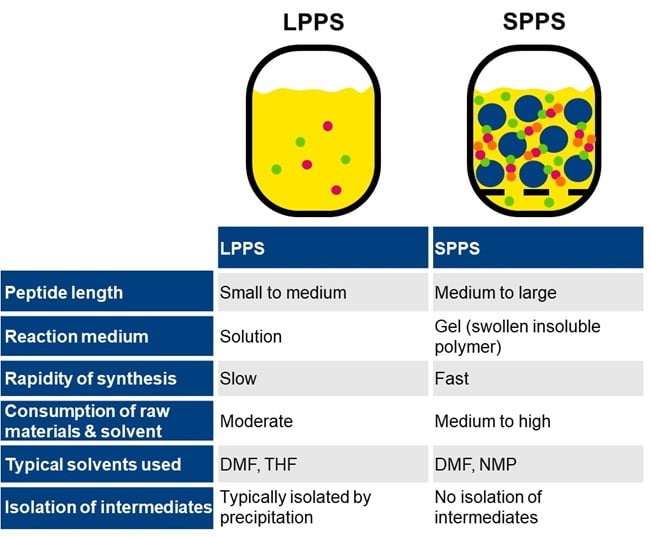

Peptide APIs – including GnRH analogues – are synthesized stepwise through a series of chemical reactions assembling a chain from monomeric components. The most common formats involve either solid-phase peptide synthesis (SPPS) or liquid-phase peptide synthesis (LPPS).

In SPPS, the peptide chain is built one amino acid at a time on a solid support, with each amino acid added sequentially until the desired sequence is achieved. On the other hand, LPPS involves the coupling of amino acids in solution, allowing for greater flexibility in sequence length and complexity. LPPS offers more convergence in the synthesis compared to SPPS, which is a purely linear approach.

Regardless of the method, peptide synthesis involves steps such as activation of the carboxyl group of the incoming amino acid, coupling with the amino group of the growing peptide chain, and subsequent deprotection and cleavage from the solid support, if applicable.

These synthesis procedures work well to produce various peptides. However, to meet customer demand, it is crucial to increase efficiency when multiple peptides are synthesized at the same time and on similar sized equipment – as adding additional reactor capacity might not be feasible. Using the specificity of GnRH analogues, we show potential efficiency improvements using synergies in the production of different peptide API.

Introducing convergent peptide synthesis: What is it, how do we do it.

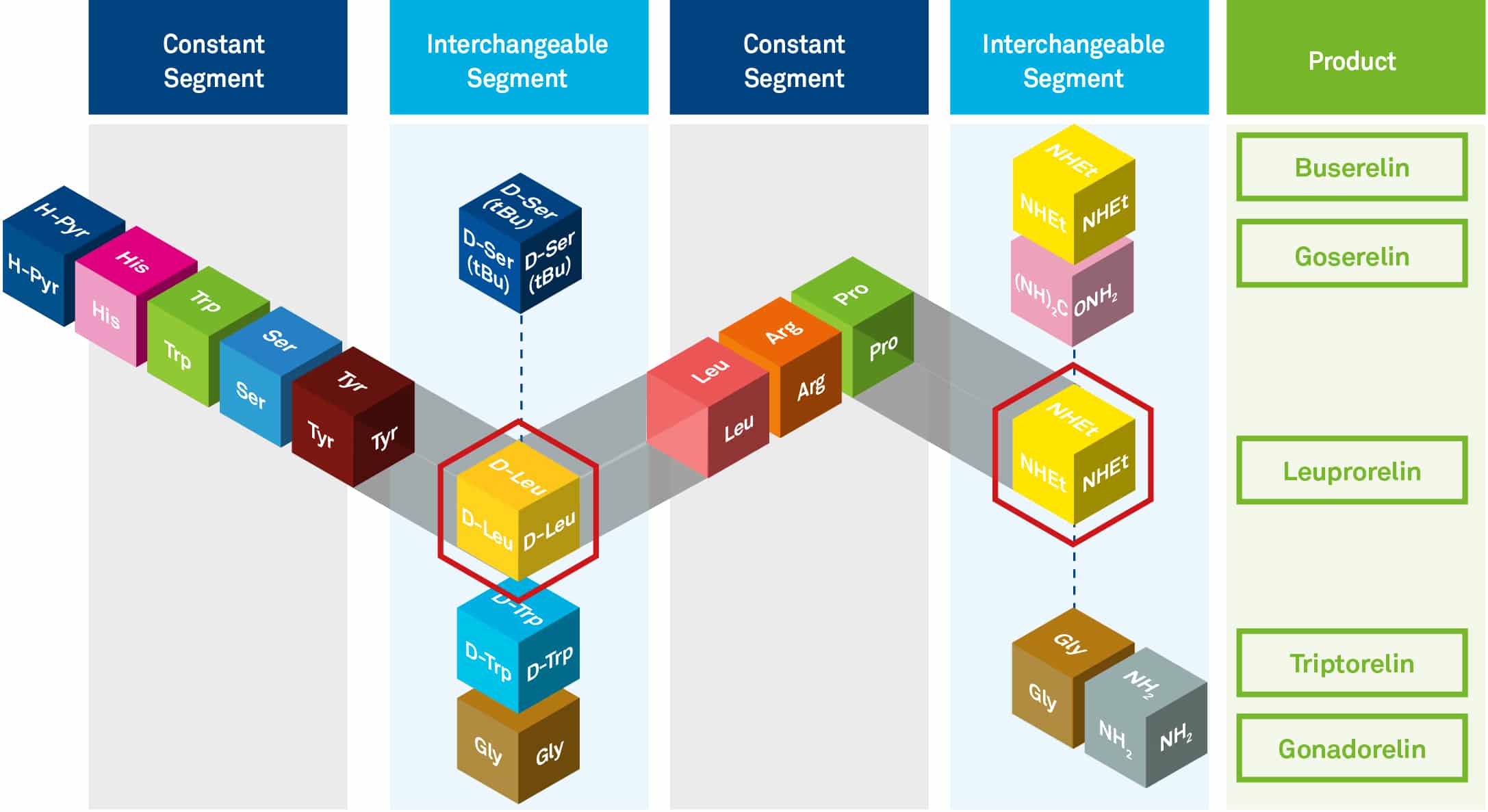

The sequences of the different GnRH analogues have amino acids in common, in what we call “the constant segment”. This shared segment between different APIs confers many advantages when optimizing manufacturing efficiency.

The general synthesis of these GnRH analogues is performed via LPPS, which enables a convergent approach. The constant segments are synthesized separately and then used in all subsequent processes. Our customer can benefit from these synergies: the convergent approach in synthesizing GnRH analogues offers advantages such as process efficiency, consistent quality, secured supply chain, advancements in development of new processes, and a faster time to market.

Benefits of converging LPPS for the synthesis of multiple peptides

Process Efficiency: The convergent approach to synthesizing GnRH analogues is a significant change in terms of process efficiency. By utilizing common steps to produce multiple analogues, manufacturers can streamline their processes, leading to significant efficiency improvements. These improvements, spanning raw materials, labor, and overall manufacturing expenses, can potentially be passed on to customers. This contributes to making these vital medications more affordable and accessible to a broader patient population.

Consistent Quality: A convergent approach promotes consistent quality in the manufacturing process. The commonality in amino acid sequences, particularly in the constant segment shared among different analogues, ensures a more uniform production process. This consistency translates into products that meet high standards across the board, reducing variability in therapeutic outcomes for patients. Customers can rest assured that the GnRH analogues they receive are consistently of superior quality.

Secured supply chain: Efficiency gained through the convergent approach plays a crucial role in securing the pharmaceutical supply chain. By synthesizing multiple analogues with a common process, manufacturers can mitigate the risk of shortages or disruptions in the supply chain. This is particularly significant in ensuring a continuous and reliable flow of medications to patients who depend on them for various health conditions.

Faster Development of New Products: Perhaps one of the most compelling advantages of the convergent synthesis approach is its ability to accelerate the development timeline for new GnRH analogues or new processes. Production experts can navigate the complexities of convergent synthesis with ease, translating into a faster time to market for innovative therapies. This swift access to new products addresses unmet medical needs promptly.

Unlocking efficiency and realizing benefits

In the synthesis of GnRH analogues, production expertise is key for unlocking efficiency and realizing a host of benefits. From process efficiencies and consistent quality to a secured supply chain and accelerated product development, the convergent approach through LPPS improves pharmaceutical manufacturing. As the pharma industry continues to supply medications for an increasing number of patients at affordable prices the role of production experts becomes increasingly important in ensuring the supply of the API.

Webinar: MITIGATING SUPPLY CHAIN RISKS IN AN AGE OF DISRUPTION

Reliable supply of active pharmaceutical ingredients is essential for the well-being of patients and global health.

Subscribe to our general newsletter

"*" indicates required fields